Power Equipment Company

Power Equipment revs up their data at the speed of business with Magnitude Process Runner

Power Equipment Company is an American success story. In 1948 two young entrepreneurs including first employee, Dave Olson, who still runs the business today, recognized the superior technology of McCulloch chain saws when they were introduced. They saw the market potential and obtained distribution rights to take the superior line of products to market.

In 2012 Power Equipment Company decided to purchase SAP to run their business which employed just over 25 people. Like others who implement SAP’s ERP there was a big change in processes to manage the business. As business grew and sales order volume continued to increase the team was stretched to keep up with the volume of transactions and the data routines involved in sales, operations, finance, inventory and many other parts of the operation. Power Equipment had to hire outside consulting and development to help to keep up with the workload and help manage complex data operations.

Challenges

The growing wholesale distribution company was struggling to manually load and update data in SAP, with complex routines, and a heavy reliance on outside consultants. The company needed a tool to streamline data management that was also easy for any business user to manage.

Holly Bierer, an entrepreneurial IT Company executive with Power Equipment, kept asking herself, is there a way for a smaller team to do more with fewer people and time involved? She faced this dilemma head on.

Holly needed a way to load data quickly and in mass. In a typical month the company was processing over 3500 sales orders, and more than 2600 purchase orders. In addition, their business required volumes of product information be updated frequently. To keep pace with those updates, each month she added about 500 new material masters.

In addition to their ongoing data needs, there were several data cleansing projects. As SAP-experienced resources were challenging to find, Holly needed a tool that didn’t require SAP expertise to run. If she could reduce time required for repetitive tasks, she would free up team members for more important, strategic needs.

Solution

From Reactive to Proactive Data Management

Magnitude Process Runner enabled Power Equipment Company to manage data faster – directly via business users.

To reduce manual operation and dependencies on outside resources, and to harness the growth of their operations, Holly looked for a solution that could help her team manage SAP data a whole new way.

Holly’s primary goal was to increase productivity. She also wanted to improve processes and the accuracy of the data. She knew that if data improved, so would the value of the data.

She researched the known available options in the market. LSWM from SAP was an option, but it took special skills to use and had limitations with scenarios she ran frequently. It would require more consultants, and that was not an option. She also looked at several data management tools.

When Holly downloaded the free trial of Process Runner she realized anyone in her company could use it. Process Runner didn’t require skills beyond the ability to use Microsoft Excel.

The choice was simple: Process Runner.

The Answer was Process Runner

Process Runner was well suited for a non-technical workforce. Holly’s teams could leverage Excel familiarity to automate data. She liked the ready-to-run templates on the Process Runner Cloud. It gave her a road map for automation. Process Runner delivered all SAP technologies in one tool, which no other vendor did. This allowed more comprehensive automation without buying multiple tools. Overall, Process Runner delivered the broadest coverage for business process automation.

Another factor in Holly’s decision was Magnitude’s support team, whom she found highly useful when she had questions during her product trial. She knew this would important over the life over the use of Process Runner.

Process Runner was an ideal fit because it was built for business users. Flexibility in licensing meant she could make implementation more affordable. As she considered future need such as workflow management, Process Runner stood out from competition.

Soon after purchase her team got to work with Process Runner. From onboarding of new products and creating many materials to adding suppliers, pricing updates, to schedule creating schedules, loading stocks, Process Runner quickly went to work processing data for Power Equipment.

Primary business drivers for change:

- Increase accuracy of the data and overall process

- Decrease effective hours to manage data

- Speed time to market by minimizing manual data input

- Address anticipated ecommerce needs

- Simplify product information system updates

- Enable internal teams to do their own work without third parties

- Secure an adaptable tool for changing business needs

Results

It was not long before the tool paid for itself. Six months and Process Runner had paid back the initial investment.

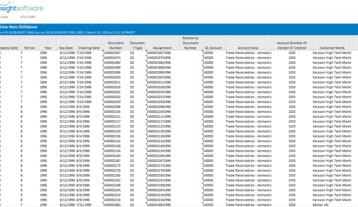

At one time, Power Equipment uploaded 900 sales orders. It took 10 minutes to create the script and 45 to 50 minutes to run Process Runner. This job alone saved the company 45 hours of manpower.

Process Runner has also allowed Holly’s team to take on new projects with quicker time to results. Users have become confident in their ability to get work done. It’s also improved the quality and the value of the data that goes into production.

Holly said simulating the processes in advance is highly valuable to creating new solutions for their needs. Holly believes that one big factor in their success with Process Runner has been the number of areas that they have improved processes including:

- Supplier Data Management

- Customer Data Creation

- Master Data Creation and Management

- Changes to Materials

- Transform Data

- Roll back with Mass Data Changes

The results have included some major improvements in the performance of the business including:

- Lower IT Reliance to assist with data

- Lower Total Cost of Ownership of SAP

- Improved Time to Market for Products to Customers

- Improved Data Quality and Data Value

Today they are a more agile, flexible organization whose users love the autonomy Process Runner enables. Getting work done faster with higher quality has helped Power Equipment achieve its goals.

We had payback on the tool in 6 months. For example, we processed 845 sales orders at one time uploaded with Process Runner, saving 45 hours of manpower. We’ve been able to take on more projects. And users love it!