The Added Value of Quality Management

There are many reasons to implement Quality Management (QM) into your supply chain. Management standards are based on seven QM Principles. The primary focus of QM is to meet customer requirements and to strive to exceed customer’s expectations. Other objectives are to increase effectiveness and efficiency, creating understanding and drive improvements, improve data-driven decision-making processes and an enhanced process performance enables a better relationship management.

Angles for SAP Quality Management

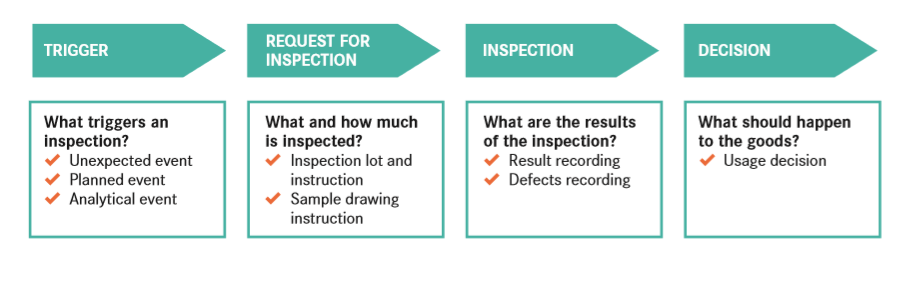

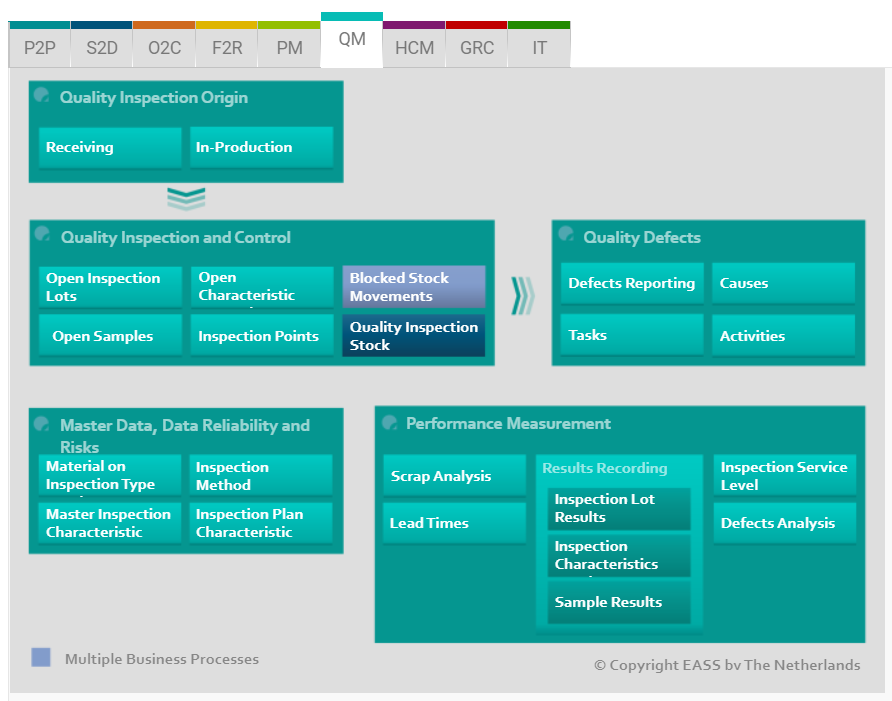

To help our customers with the seven QM principles, we have added QM as new business process to Angles for SAP. QM is an integral part of the supply chain and logistics function in the SAP system; it relates to processes in MM, PP and PM. It is especially important in warehouse and manufacturing operations when quality inspection is executed. For example, quality checks at inbound and outbound warehouse processes and during or after manufacturing process steps. The core process of QM is the inspection process and all of the steps belonging to it.

This process has been visualized in the Activity diagram. Five main activities have been identified:

- Quality Inspection Origin (trigger of the process)

- Quality Inspection and Control (execution of the process)

- Quality Defects (results of the process)

- Master data maintenance (maintenance/customizing of QM process)

- Performance Management of the QM process (analysis on results of QM process)

Within all main activities, sub activities are defined. You can select the activity you want to analyze by clicking on the activity. This will open a Template with several Displays that you can use to answer your business questions.

In the data model for QM all the important tables/objects from the QM process including their relationships (references) are available. The data model is very helpful when you want to create customized angles using pre-defined references and/or jumps.

Of course, wherever relations exist to other parts of the Angles for SAP model, these relations are also provided. In this way, the QM business process integrates with the already existing processes within Every Angle. The QM business process completes the data model by not only providing the Quality Inspection Lot and its general result, but also by providing the detailed results of the inspection process on different levels, linked to the relevant master data objects.

Integrating Angles for SAP QM into your supply chain, will help you answer questions like:

- How can I better control the planning and timely execution of all our QM process activities?

- How can I analyze the different quality results and translate this into actions/improvements?

- How can I control the master data to enable an effective execution of your SAP QM processes?

This video explains how you can easily get answers to the above and more business questions – on a generic or detailed level.

If you want to start using Angles for SAP QM, you can contact us via our contact page, or submit a ticket via our Support Portal.